Industrial thermal insulation

Business owners and facility managers have trusted Termisol Termica for premium industrial heat insulation, anti-condensation and corrosion protection

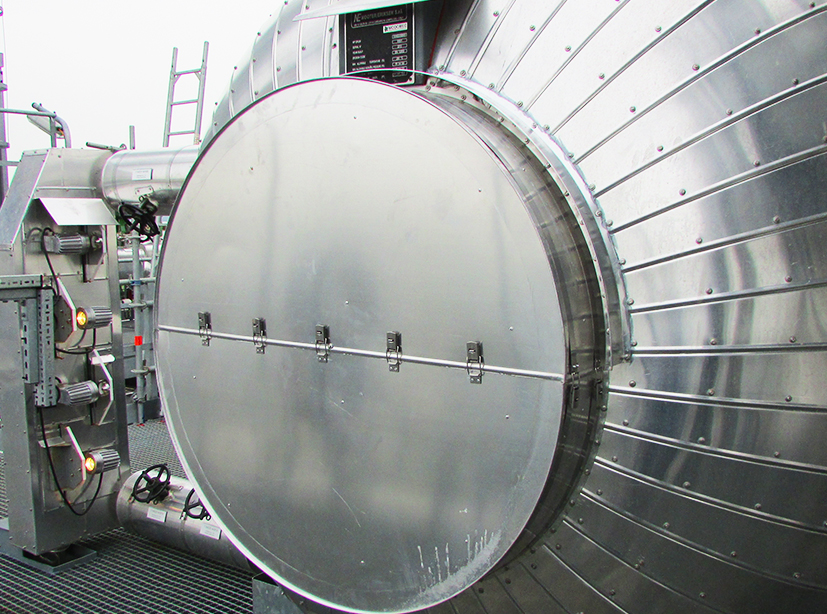

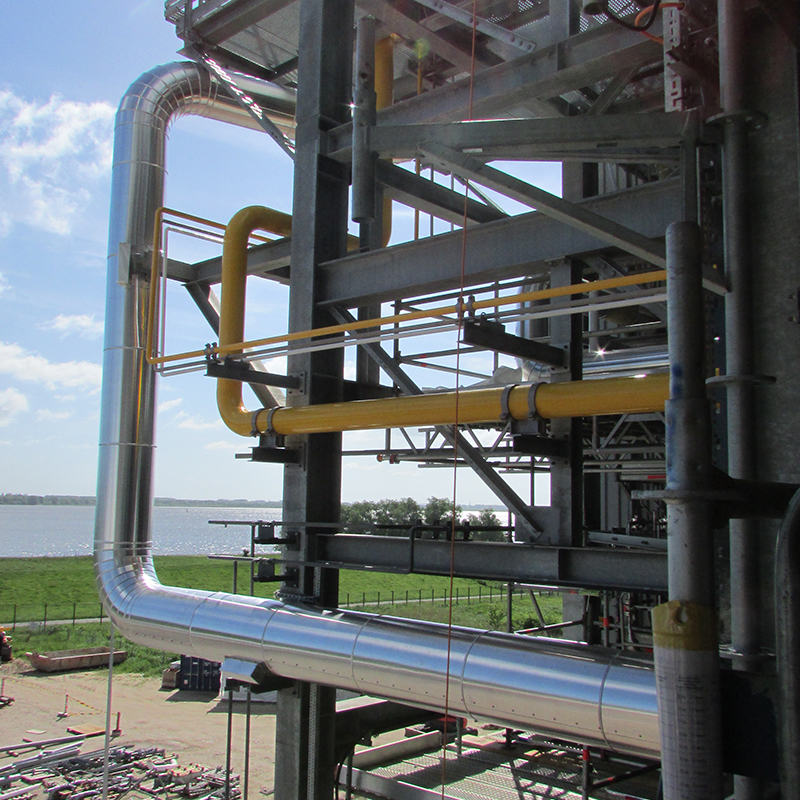

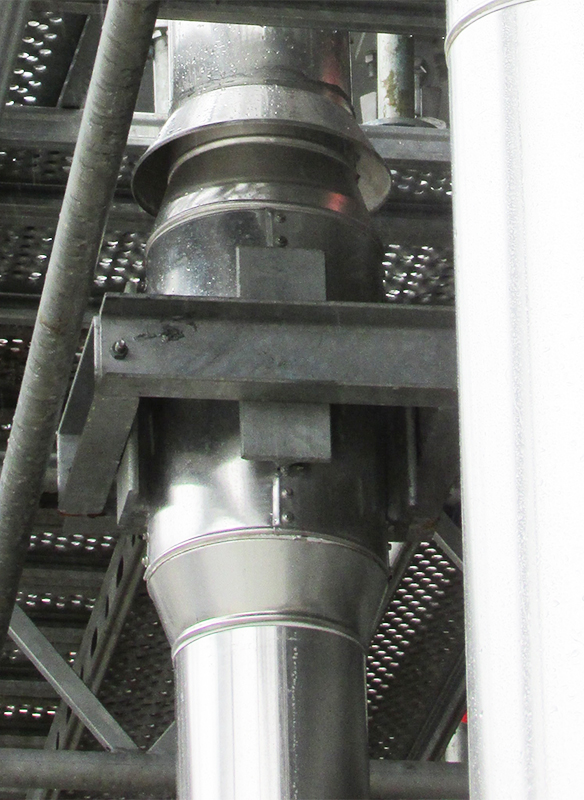

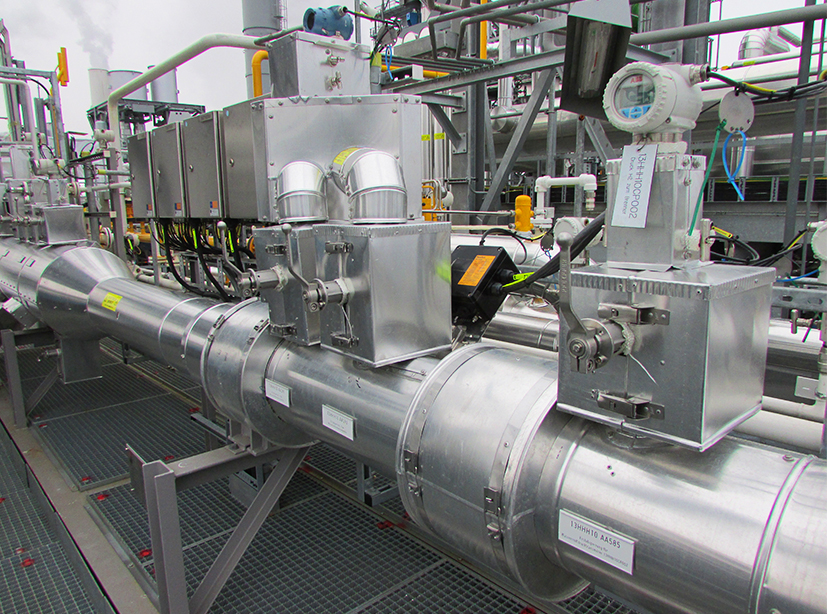

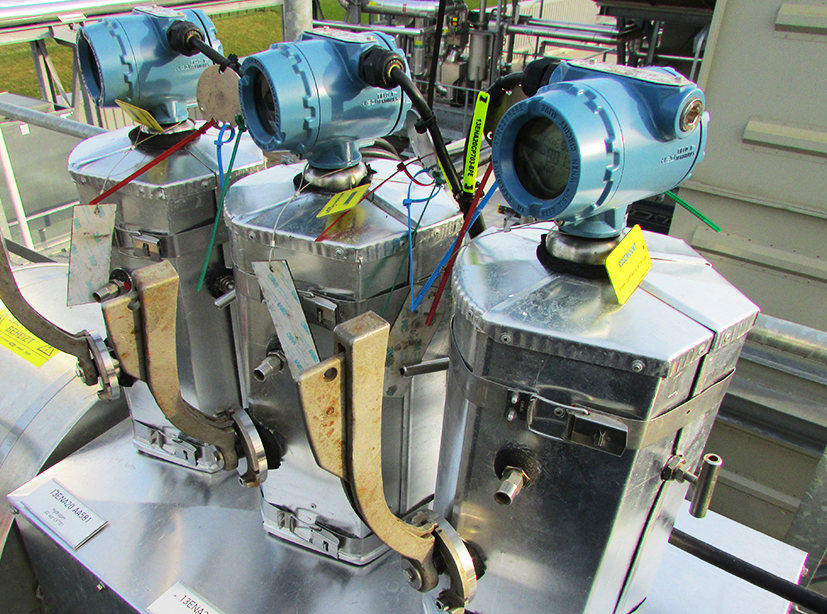

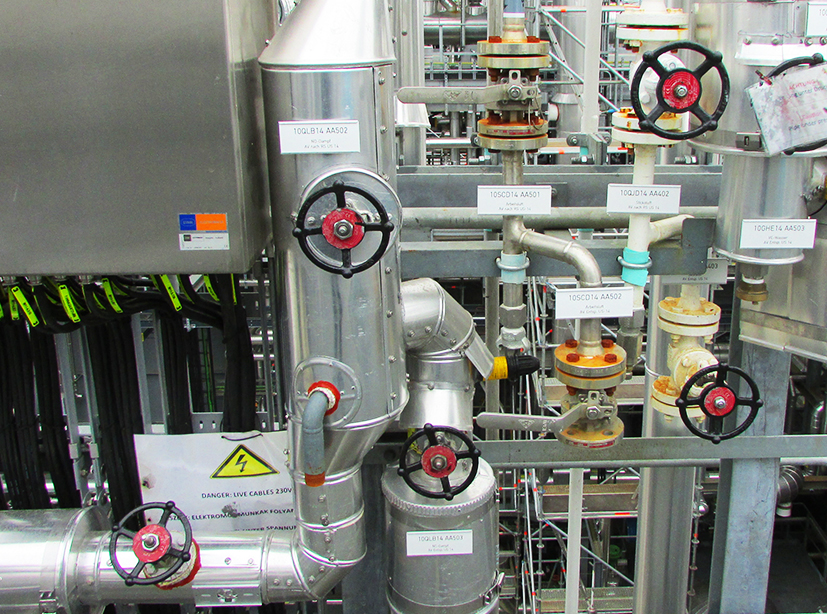

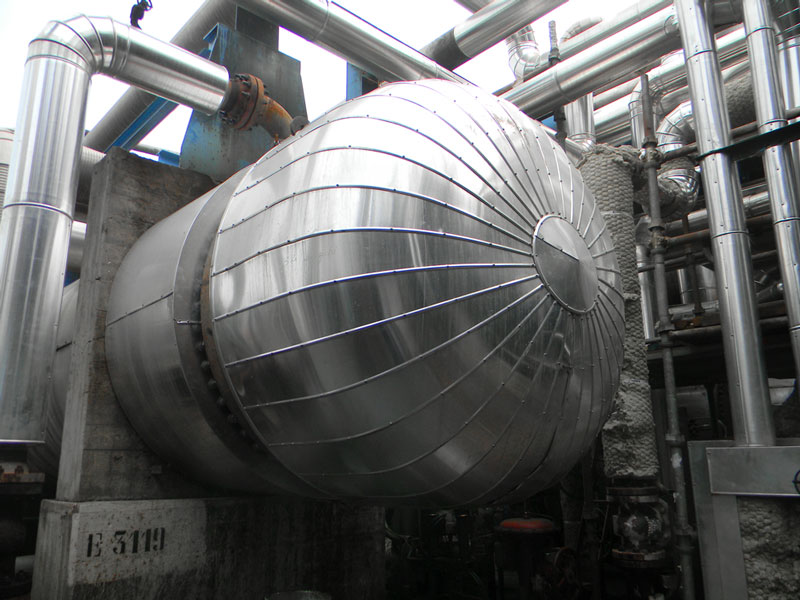

We have developed great expertise in the field of industrial thermal insulation and can provide any kind of technical solution, design and installation both for hot, cold and cryogenic insulation using the most performing and innovative thermal insulation materials available on the market.

working closely with our many suppliers, we select the most efficient insulation type to meet budget and energy saving needs. Our goal is to get the best products available at the best price. So, we use mineral wool, glass wool, Foamglas, Pyrogel XT, Pyrogel XTF. For cryogenic insulation we use Foamglas, Rigid Preformed Polyurethane or Phenolic Resin Insulation System; cryogel Aerogel Insulation System.

For new construction and existing facilities

Thermal insulation has to be considered both for new construction and existing facilities. In general, any system that carries or stores liquid, gas, air, or product in which the temperature of the substance being transferred or stored is impacted by the temperature of the ambient air requires thermal insulation.

Limit the heat loss

Insulation helps mantaining the process temperature to a pre-determined value, but insulation thickness must be sufficient to limit the heat loss in a dynamic system or limit the temperature drop, with time, in a static system.

Save energy

Properly designed and installed insulation systems immediately reduce the need for energy: saving on heat loss, product and equipment performance, condensation problems, personal protection and energy conservation.

We are ISO 9001, ISO 14001 and OHSAS 18001 certified

We are ISO 9001, ISO 14001 and OHSAS 18001 certified, underpinning our commitment and approach to quality assurance, and health and safety, whilst fulfilling our obligation to the care of the environment.

With the nowaday greater regulatory pressure on minimizing energy consumption and maximizing energy efficiency of industrial systems and processes thermal insulation has to be considered as a means to ensure energy compliance. Installing cost-effective insulation promises payback times most often one year or even less, but proper thermal insulation not only saves money, it also lowers energy consumption and green house gas emissions (“Climate protection with rapid payback“, Ecofys report commissioned by EiiF, 2012).

European Industrial Insulation Foundation

Through our certified TIPCHECK Engineers – which are also II level Thermographs (UNI EN 473) – we perform the TIPCHECK Programme, the standardized thermal energy auditing tool established by EiiF, European Industrial Insulation Foundation to evaluate the performance of industrial insulation systems and advice on how to increase energy efficiency and savings.