TIPCHECK

With our certified TIPCHECK Engineers as well as II level Thermographs (UNI EN 473) we perform the TIPCHECK Programme, the standardized thermal energy auditing tool established by EiiF, European Industrial Insulation Foundation to evaluate the performance of industrial insulation systems.

It is demonstrated that bad insulation, uninsulated parts, unsufficient insulation or damaged insulation mostly represent:

Energy Consumption

A waste of energy and money

Environment pollution

CO2 emissions in the environment

Safety risks

Safety risks for operating personnel

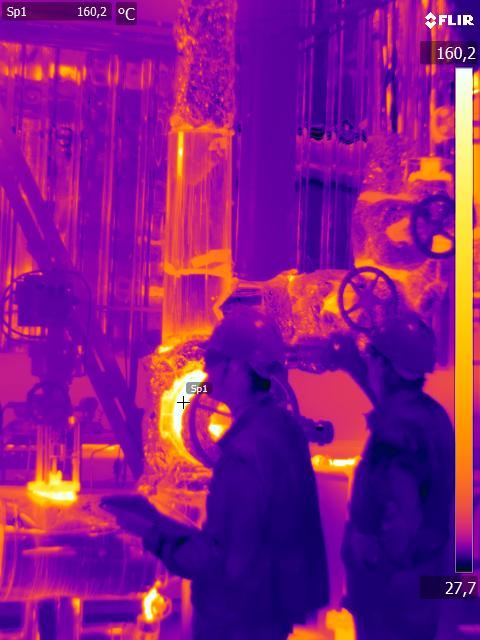

A TIPCHECK (Technical Insulation Performance and Check) evaluates insulation systems of existing facilities, planned projects or retrofits. It’s non-invasive audit that can be performed also during plant’s normal work and, thanks to thermal imaging, immediately can identify heat anomalies and losses.

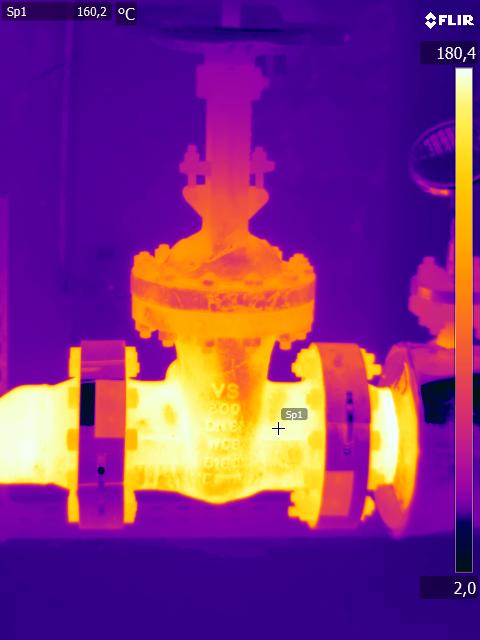

After gathering the necessary information and making a visit to the industrial plant we proceed with to the actual audit, carried out mainly with thermal imaging cameras. Thermal imaging is a method that allows to perform remote measurements of temperature and thermal gradients on stationary objects. Thermography measures surface temperatures, EM radiation emitted by bodies in two specific portions of the IR spectrum, thus exploiting the physical principle to any body which has a temperature greater than absolute zero ( -273.14 ° C ) emits energy in the form of infrared radiation.

The “energetic vision” is detected by the imager in the form of a color image, thanks to the combination of a color palette with a range of temperatures. Upon completion of the data other investigations are carried out using thermal imaging probes and plates. The collected data are now ready by digitalized and processed by our experts. Our TIPCHECK Engineers are thus able to quantify the amount of energy and money that a plant (or part of it) is possibly losing in the current configuration and to calculate the potential savings.

TIPCHECK demonstrates how more efficient insulation could:

- Save energy

- Save money

- Improve process efficiency

- Reduce CO2 emissions and create a cleaner environment

- Reduce Safety risks for personnel